Difference Between Heat Treatment and Annealing

Table of Contents

Key Difference – Heat Treatment vs Annealing

The key difference between heat treatment and annealing is that annealing is one method of heat treatment. Heat treatment processes involve heating and cooling operations sequentially. Heat treatment and annealing processes change the metallurgical structure and alter the physical, chemical, magnetic and mechanical properties of the material.

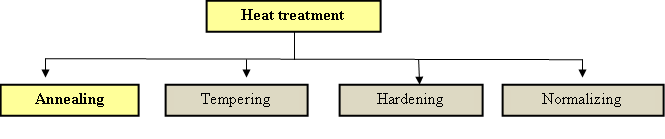

Heat treatment includes four main processes; normalizing, annealing, hardening and tempering.

What is Heat Treatment?

Heat treatment is a combination of several processes; heating at a specific rate, soaking at a temperature for a certain period, and finally cooling at a specific rate. It has the surface and bulk processes. This entire process helps to modify the microstructure of the material. Heat treatment methods provide so many advantages to the man, changing material properties of metals (physical, mechanical, magnetic or electrical).

The most commonly used bulk processes in heat treatment methods are annealing, tempering, hardening and normalizing. One method or a combination of several heat treatment methods together is used simultaneously to get the required microstructure of the material.

Castings fresh from the heat treatment furnace

What is Annealing?

Annealing is a process used in metallurgy; it alters the physical and sometimes chemical properties of the metal material. Annealing increases the ductile property of a material to make it more workable. In annealing, the material is heated to a high temperature, and then it is cooled at a very low rate to the room temperature. The resultant material is ductile and tough, but has low hardness value.

- Ductility: the ability to deform a material under tensile stress.

- Toughness: the ability to absorb energy and deform plastically without fracturing. In other words, toughness is the amount of energy per unit volume that a material can absorb without cracking.

- Hardness: the ability of a material to resist plastic deformation. Less hard materials are easy to deform and the vise versa.

Annealing a silver strip

Annealing is done by heating the material to a particular high temperature (this temperature differs depending on the requirement and the type of metal) in a furnace and then it is soaked at that temperature. Next, the furnace is shut off while the metal is inside.

What is the difference between Heat Treatment and Annealing?

Definition of Heat Treatment and Annealing

Heat treatment: Heat treatment is the Process in which a metal is heated to a certain temperature and then cooled in a particular manner to alter its internal structure for obtaining the desired degree of physical and mechanical properties

Annealing: Annealing is the process of softening a material (such as glass), metal (such as cast iron), or an alloy (such as steel) to make it less brittle by heating it to a particular temperature, maintaining it at that temperature for a particular duration, and cooling it slowly to normal temperature at a particular rate.

Characteristics of Heat Treatment and Annealing

Methods

Heat Treatment: Most commonly used heat treatment methods are; annealing, normalizing, hardening and tempering.

Annealing: Most commonly used annealing methods are; stress relieving, soft annealing, recrystallization annealing, standardized annealing, solution annealing, stabilization annealing and magnetic annealing (permeable annealing).

Process

Annealing: It has three main steps in the process.

- Heating the material to a temperature above the critical temperature.

- Holding the material at that temperature for a certain period.

- Cooling at a slow rate inside the oven.

Cooling is done once the required properties are obtained. The cooling process should be done at a certain cooling rate while protecting the acquired properties.

Heat Treatment: All the other heat treatment methods have the same steps as above. But heating and cooling rates and the soaking temperature change according to the requirements.

Changes in Properties

Annealing: Annealing changes the following properties of the material.

- Reduction of stress.

- Improve the structure of material

- Improve the magnetic properties

- Reduction of hardness

- Improve the welding properties

- Improve the corrosion resistance

- Good dimensional and shape accuracy

- Clean process, parts remain bright

Heat treatment: In heat treatment, different methods change different material properties. Some examples are listed below.

- Bulk hardening, surface hardening – increase the strength, hardness, and wear resistance

- Tempering, recrystallization annealing – increase the ductility and softness

- Tempering, recrystallization annealing – increase the toughness.

- Recrystallization annealing, full annealing, normalizing – to obtain fine grain size

- Stress relief annealing – remove the internal stresses

- Full annealing and normalizing – improve the machinability

- Hardening and tempering – improve the cutting properties of tool steels

- Recrystallization, tempering, age hardening – improve the electrical properties.

- Hardening, phase transformation – to improve the magnetic properties.

ncG1vNJzZmivp6x7pbXFn5yrnZ6YsqOx07CcnqZemLyue8OinZ%2Bdopq7pLGMm5ytr5Wau260xJqrZqyimq61ucSnq2aZnpl6t7%2BMmqWnnZGhtq%2Bzjg%3D%3D